Students perform high-precision measurements of complex geometry components (0.0001 in). The machine performs direct measurements using a probe and sending coordinates to a drawing software that illustrates the dimensions.

We have an optical comparator, a digital heights gauge, two portable roughness testers and a CMM machine in which we carry out demonstration of functioning and operation for the different metrology subjects of all educational levels.

Classes about Aircraft Systems, Avionics Systems, Communication Systems, Measurement of Aircraft Systems, Electricity, Multisensory Systems, etc. are given in this laboratory. Here, students carry out activities such as practices with GPS, communication practices, power measurement, reflected wave and VSWR tests, modulation practices, time domain and frequency domain practices, ILS practices (LOC, GS), Marker beacon, Navigator, ARINC 429, Use of Ramps, EFIS screens tests, static electricity tests, practices with passive elements (R, L, C), some magnetism practices, board manufacturing using software, as well as practices of navigation instruments.

In addition, some students perform their social service developing and creating teaching material, providing maintenance of the laboratory, facilitating use of the flight simulator and some school projects.

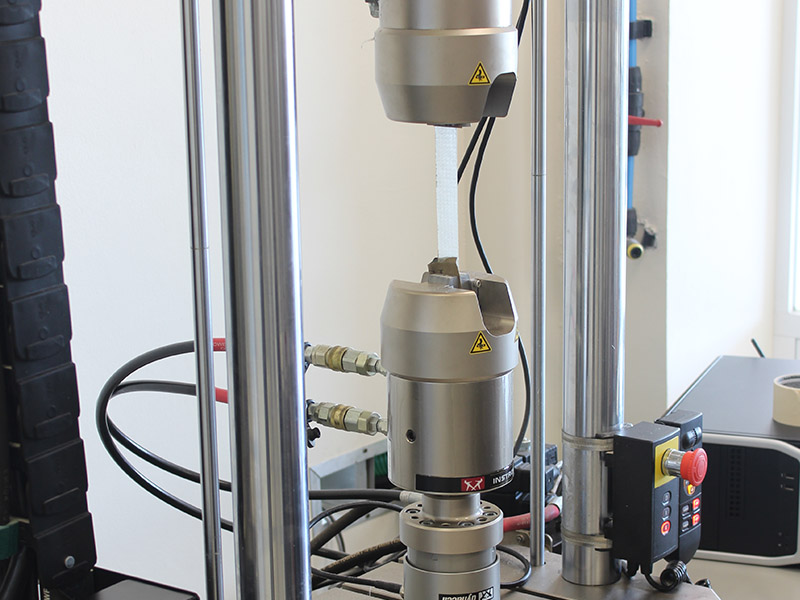

Students study materials such as: compounds, metals and polymers used in aviation to determine their viability, as well as their useful life in the aeronautical application.

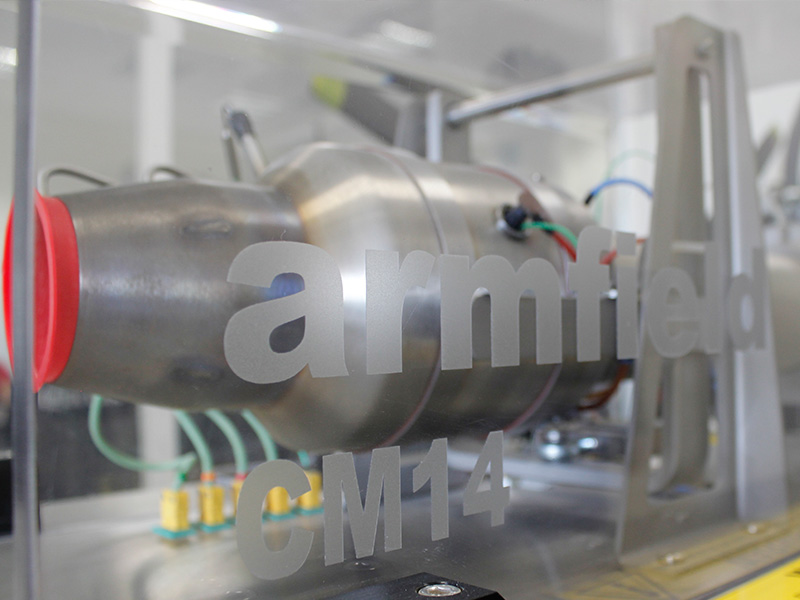

Students in the Thermal Machines workshop perform component identification tasks of a CM14 centrifugal compressor (Turbojet) basic turbojet engine test cell for familiarization purposes with the test procedures on Gas Turbine engines used in aviation.

The student carries out identification activities of a workshop of this type, safety standards and MSDS, handling of chemical materials, layout of a workshop of this type, general operation, evaluation of the applied processes, and comparison of equipment according to each process, identification of equipment for chemical spills, complementary accessories, and regulations. The student performs familiarization activities in a work-like environment.

Among the activities carried out in the cleaning line are mechanical cleaning activities, chemical cleaning by immersion and aeronautical grade ultrasound. The student identifies the different types of equipment, such as the type of tub to be used, control equipment, operation equipment and its layout, personal safety equipment according to the chemical agent, and complementary accessories. Students learn to operate the line, to follow a procedure and learn to process test panels. They perform activities to compare types of cleaning, their application, and advantages / disadvantages. They perform evaluation activities of each type of cleaning.

Among the activities of the Passivation line, students carry out practices to understand the concept of passivation and its application in aeronautics. They identify the equipment, the type of tubs, control, operation, layout, and personal safety equipment according to the chemical agent, and complementary accessories. They learn to operate the line and to process test panels. They carry out evaluation of passivation.

In the chemical conversion line, students carry out practices to understand the concept of chemical conversion and its application in aeronautics. They identify equipment, such as the type of tub to be used, control equipment, operation equipment, layout, personal safety equipment according to the chemical agent, and complementary accessories. They learn to operate the line and to process test panels. They perform evaluation activities of a chemical conversion.

Finally, in the anodizing line, students perform practices to understand the concept of anodizing and its application in aeronautics. They identify equipment, such as the type of tub to be used, control equipment, operation, power source, arrangement of electrochemical cell for an anodizing, the layout, personal safety equipment according to the chemical agent, and complementary accessories. They learn to operate the line and to process test panels. They perform sealing activities on the anodizing and perform evaluation activities for anodizing.

Students at the Aerodynamics Laboratory develop visualization practices of flow effects on surfaces and aerodynamic models using an open-loop subsonic wind tunnel.

Practices involve measuring forces, pressures around a body, as well as the possibility of designing and testing their own designs in the wind tunnel.

In this lab, subjects such as Electricity, Electricity and Magnetism, Electronics, Digital Electronics, Microprocessors, Electrical Circuits, etc. are offered.

Here, students perform various electrical and / or electronic circuits in the context of design and troubleshooting, using the different measurement equipment available on the workbenches (Function Generator, Oscilloscope, AC / CD Sources, Portable and Bank Multimeter, Logic Tip, etc.). Students put into practice the different concepts studied in class in a practical and concise manner that leads them to the understanding of the electrical and electronic issues of aircraft.

Equipment for the preparation of metallic, ceramic and composite samples is located in this laboratory. The equipment allows for suitable surface finishes in studies and research of microstructure and engineering measures (grain size, phase distribution, heat treatment thicknesses) of the materials. These studies are fundamental to determine the properties of the materials.

Likewise, in this laboratory there is a session dedicated to the characterization of the samples by light microscopy (a 3X microscope, 1 inverted-metallographic stage microscopes with 1000X capacity and a 2 mm resolution microscope, with double system of illumination that allows the observation of the following modes: light field, dark field, polarized light and transmitted light). The laboratory also has a universal hardness tester where hardness measurements can be made using Rockwell (B and C), Vickers and Brinell hardness methods.

A viscometer and a potentiostat are installed in the laboratory. These are instruments for research related to new natural origin fuels.

This laboratory is used as a classroom, practice laboratory and research laboratory for nanomaterial projects with aerospace applications.

In this laboratory, students develop some of the following activities: comprehension and understanding of new generation aircraft systems such as electric, pneumatic, air conditioning, engines, hydraulic, navigation, oxygen, fuel, etc. They also understand the description, location, operation and visualization of the aircraft systems and their components. They can also improve their proficiency of aeronautical technical English with the support of audiovisual equipment related to the software used.

On the other hand, since we have the Virtual Maintenance Trainer VMT A320 (VMT A320 VIRTUAL MAINTENANCE TRAINER), students can perform activities such as localization and visualization of 3D aircraft systems and components, operation of systems schematics and real-time cockpit procedures (multiple screens), operational and functional tests related to the aircraft systems according to the applicable technical documentation, removal and installation of components, and failure analysis in different aircraft systems. They also interact with technical documentation (manuals) of the aircraft, etc.

Students have the possibility to practice and gain experience in the different authentic aviation equipment that can be found at UNAQ, such as:

Carretera Estatal 200 Querétaro – Tequisquiapan No. 22154

Col. Parque Aeroespacial de Querétaro.

Colón, Querétaro. México

C.P. 76278

Teléfono: (442) 101 66 00

2022 | Universidad Aeronáutica en Querétaro